Product Description

When the Rotary Activated Furnace works, the carbide is added to the top hopper, and the feeding device feeds the carbide into the furnace quantitatively and continuously. Driven by the reducer of the stoker, the gear meshing makes the burden layer on the furnace bed be constantly turned over, the temperature of the carbide is constantly rising, the furnace body has a tilt during installation. With the rotation of the furnace body, the carbide material moves gradually to the middle of the furnace under the driving of its own gravity and inertia, and then again. Move intermediate to end outlet. Repeated this way, the material moves slowly from top to bottom, and the activated carbon is activated by the moving process and through the steam, and discharged from the tail outlet. The temperature of each section can be adjusted through combustion. The flue gas of combustion products and the water vapor from the inlet of water vapor in the furnace wall move up and down in the opposite direction to the material, and contact with the material countercurrent for activation, and eventually discharge from the flue gas outlet of the furnace top. The furnace wall is also provided with an air inlet, from which a certain amount of air is injected into the furnace, and the combustible gas produced by the activation process of water supply steam and carbon materials is fully burned and used, and the activation temperature is maintained. The residence time (activation time) of the activated carbon material in the furnace is controlled by the frequency converter to adjust the speed of the motor. The equipment uses high temperature tail gas to drive the waste heat boiler to produce steam for activation, without adding any fuel.

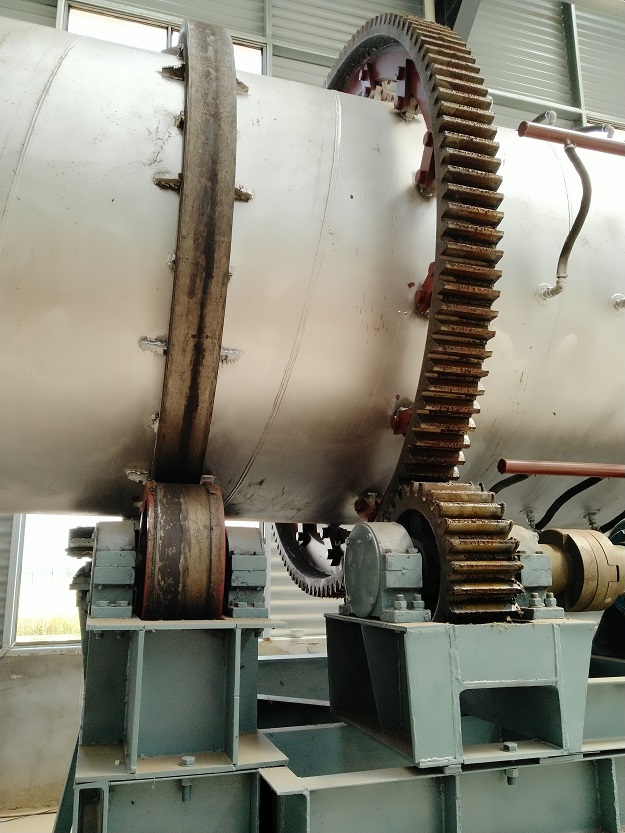

Rotary Activated Stove for the production of activated carbon rotary activation furnace: Activated Carbon Processing Equipment is a cylindrical industrial furnace, the outer wall of steel structure, the inner wall of refractory masonry. The furnace body is equipped with two rotating rails and a giant high-strength gear ring. The whole furnace body is supported by two sets of high-strength steel wheels and driven by a motor reducer. The smooth and uniform rotation of the whole furnace body is driven by the meshing of the gears. The contact surface between the charging layer and the activated gas in the furnace is constantly updated to ensure uniform activation. In order to prevent the gear from damaging the hearth, there is a l~1.5mm gap between them. Activated steam pipes with air inlet, steam inlet, observation hole and inlet hole are installed according to the need for easy operation and maintenance. The top of the furnace is equipped with automatic feeding device and flue gas outlet, and the tail of the furnace is equipped with activated carbon product outlet and cooling device.

Parameter:

Model:φ2m*20m

weight:60t

Appearance Size :24m*8m*5.5m

Output:2-2.5t (/day)

Power:32KW

In addition, our company also sells Rotary Carbonization Furnace, SLEP Furnace , Activated Carbon Regeneration Furnace (external Heating) and matching flour mill grinding activated carbon production process, Activated carbon Dedusting Equipment, Activated carbon Crushing Equipment, Activated carbon Conveying Equipment, Activated carbon Drying Equipment.

Mobile Phone: +8613153736907 +8613153738637

Wechat:+8615864124409

Address: No. 024, Quan Fulu West, Surabaya County, Jining, Shandong

Country: China

If you have any questions, please contact with us directly. Welcome you can visit our Factory.For inquiry,Please send mail directly to us.

© 2019 CHINA WAY. All Rights Reserved.Shandong Hengyi kaifeng Machinery Co.,Ltd,Inc. All Rights Reserved. Sitemap. Sitemap.html